Manufacturing & engineering Services

precision. performance. proven.

Rocky Mount, North Carolina

For over three decades, Babington has delivered precision-engineered, American-made equipment to the U.S. military, disaster relief operations, and commercial markets.

From concept to deployment, we specialize in custom fabrication, advanced prototyping, systems integration, and technical support—all executed under one roof at our 127,000 square foot manufacturing facility in Rocky Mount, North Carolina.

We don’t just build to spec—we engineer to perform. Our value-added capabilities include:

Design-to-delivery engineering grounded in Quality Function Deployment (QFD) and systems engineering principles.

Metal fabrication and component assembly, including fiber-optic laser cutting, robotic press forming, TIG welding, CNC machining, and electrical integration.

Advanced 3D modeling, finite element analysis (FEA), and computational fluid dynamics (CFD) simulation.

Field-proven system integration, from stand-alone appliances to fully containerized platforms.

Government-compliant QA and ERP systems for full traceability and mission readiness

Whether you need contract manufacturing, next-generation field kitchens, or specialty off-grid heating systems built for the harshest environments, Babington delivers operational readiness through engineering and manufacturing excellence.

Engineering & Manufacturing Services

manufacturing operations

Babington delivers full engineering and manufacturing services through integrated operations, ensuring quality, efficiency, and field readiness.

Metal Fabrication & Component Assembly

System Integration & Functional Testing

Product Testing & Certification

Quality Assurance & Final Inspection

Field Service & Lifecycle

Crating, Packaging & Delivery

Installation & Fielding Support

Operator Training & Technical Field Services

Repair, Maintenance & Lifecycle Sustainment

Warehousing, Logistics & Inventory Management

Supply Chain & Strategic Sourcing

Production capabilities

Our advanced engineering and production capabilities enable high-precision, scalable manufacturing from prototype to deployment.

3D Design, Modeling & Simulation

High-Precision Fiber-Optic Laser Cutting

Automated Press Brake Forming with Robotic Tool Changer

CNC Machining

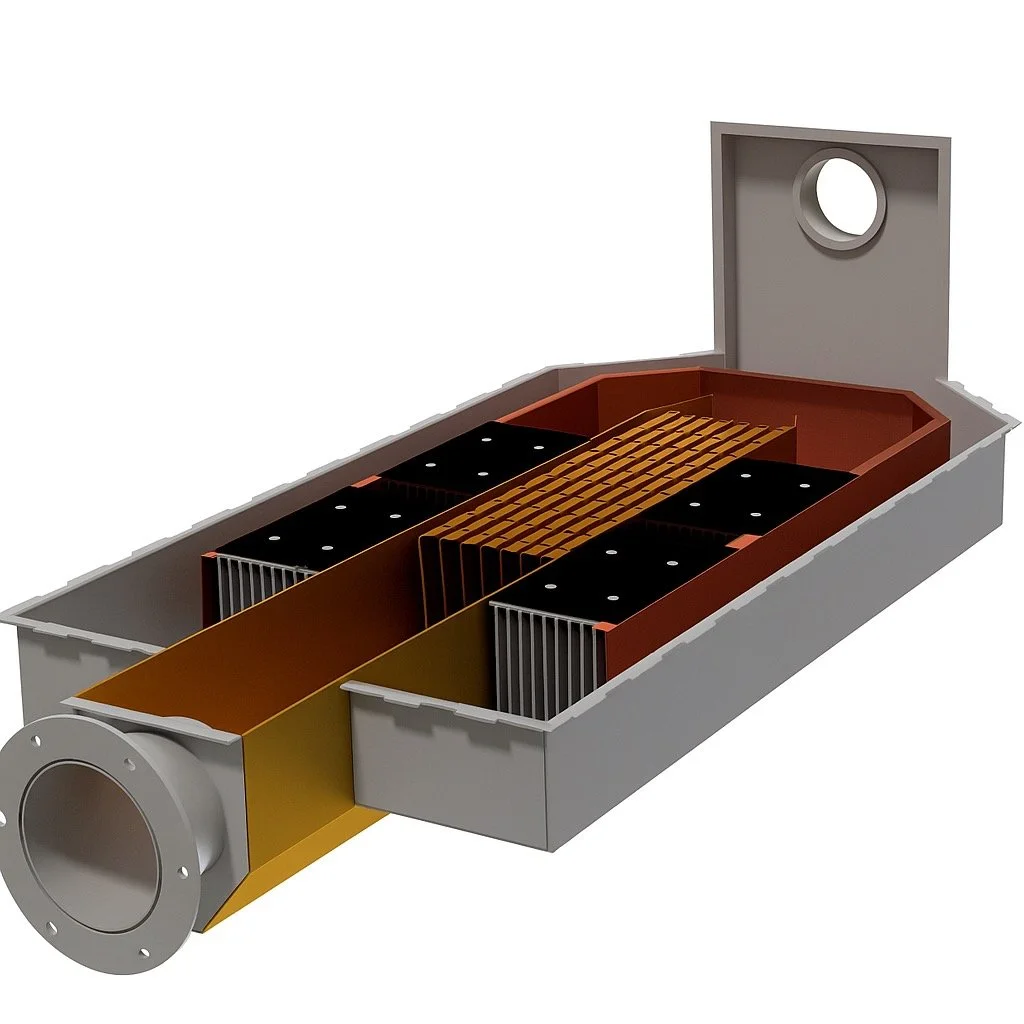

Liquid Fuel Combustion, Heat Transfer & Emissions Analysis

Shelter Testing & ISO Certification

Crating, Packaging & Final Quality Assurance

Bystronic Fiber-Optic Laser Cutting System

Bystronic 220-Ton Press Brake with Robotic Tool Changer