Engineering

Product Design & Development

Babington Burner Combustion Testing

National Oilheat Research Alliance

Plainview, NY

our approach

One Team. One System. One total development

Babington’s engineering philosophy combines systems thinking with cost discipline to deliver innovative solutions—on time and on budget. We use a top-down, iterative approach to identify customer needs early and manage costs throughout the Product Development Process (PDP), including:

Product Definition Stage

Preliminary Design Stage

Detailed Design Stage

Dedicated product teams drive each project—supported by cross-functional experts in engineering, marketing, purchasing, and manufacturing. Using proven methods like Quality Function Deployment (QFD), we translate customer requirements into technical performance targets, aligning every detail with lifecycle cost and mission success.

Whether designing new platforms or modernizing existing systems, Babington delivers engineering you can trust—from the burner and beyond.

case study

Engineering The Next-Generation Containerized Kitchen

the Enhanced containerized kitchen (CK-E)

the Customer:

U.S. Army

Description:

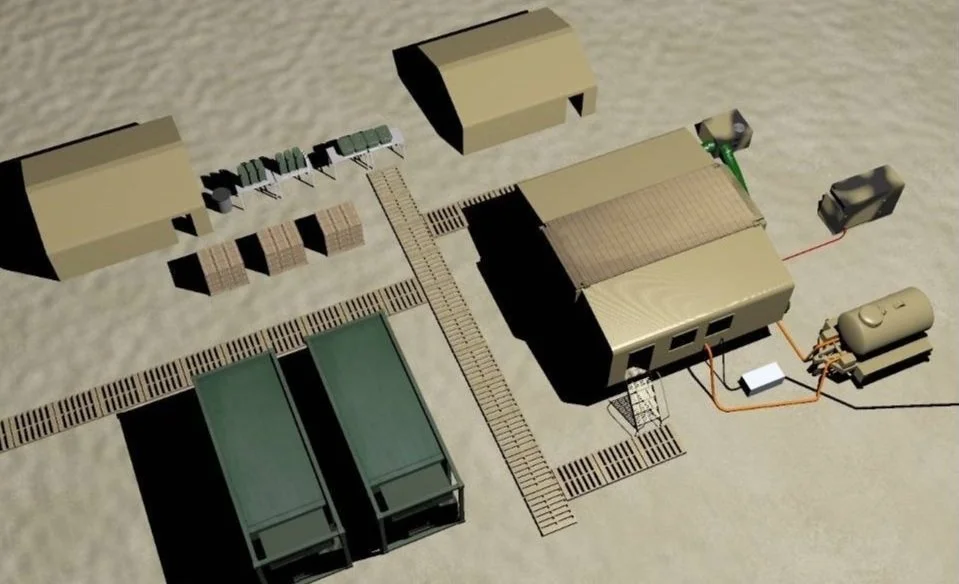

The Army Containerized Kitchen (CK) is a self-contained mobile field feeding system configured in an 8-ft by 8-ft by 20-ft expandable container-shelter that provides a rapidly deployable food preparation capability. The CK can prepare any type of food, including military UGR-H&S and UGR-A rations and is transportable by a 7 1/2 ton, 4-wheel trailer and capable of feeding up to 800 soldiers three times per day.

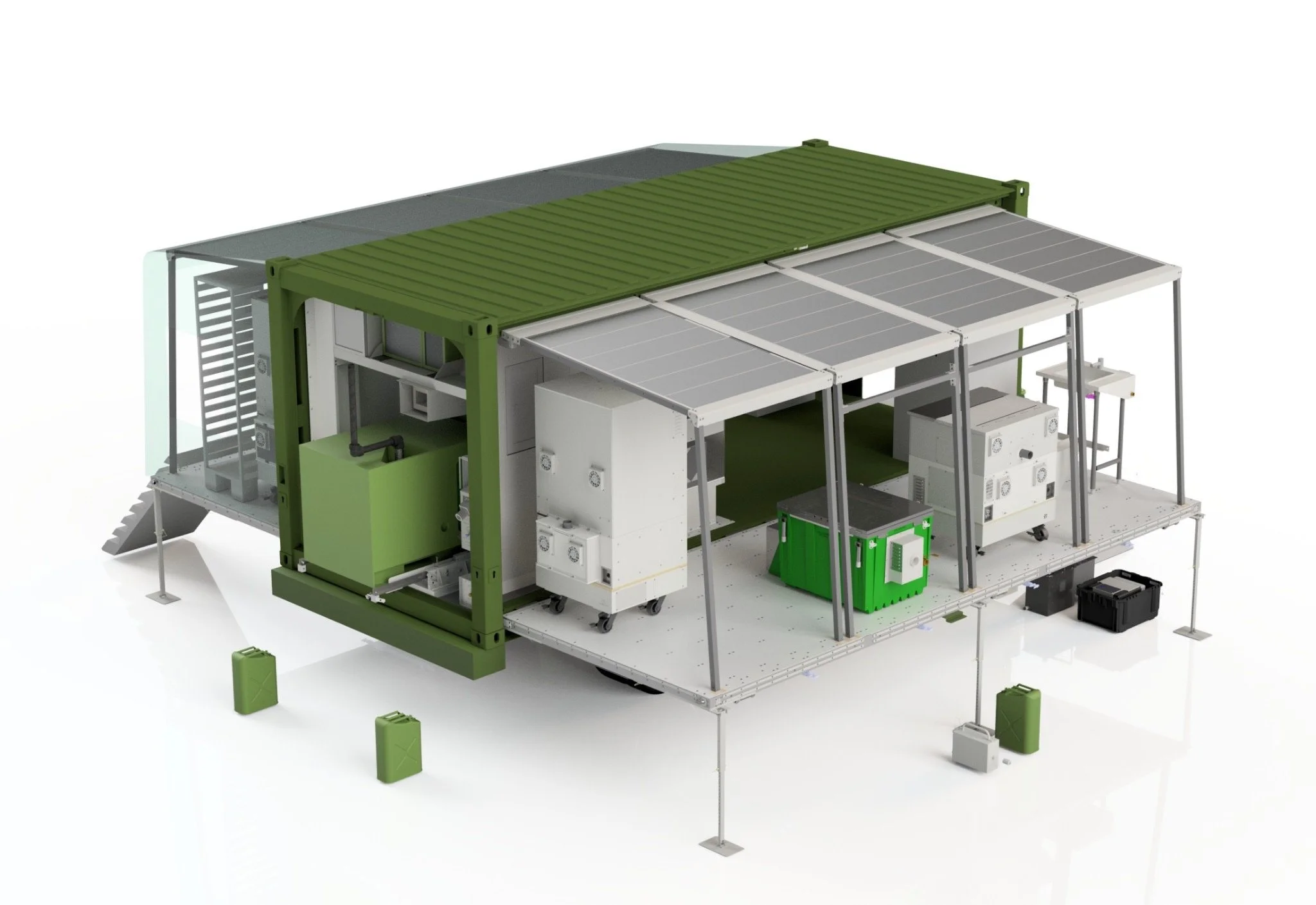

Upgrade and modernize the Army’s largest field feeding platform into a safer, more user-friendly, and energy-efficient system by integrating Babington’s closed-combustion appliances, engineering an improved wing wall and winch system, and redesigning the mechanical room for better access, safety, and serviceability. The objective: extend the CK’s operational life, improve crew safety and comfort, and lower long-term sustainment costs—while maintaining the system’s full feeding capacity.

the objective:

The Army’s legacy CK—originally fielded in 2001—is aging and increasingly unsustainable, with many units approaching 25 years in service. The core challenge: develop an upgraded system that solves key performance and safety issues while reusing as much of the existing CK infrastructure as possible. The effort required targeted engineering by the Babington team to correct known problem areas and introduce value-added enhancements for improved functionality.

Key issues included:

Failing wing walls, degraded flooring, and rust-prone components.

Excessive internal heat and noise from open-flame appliances.

Ventilation failures causing carbon monoxide (CO) exposure risks, and underperforming ECUs.

Complex generator servicing and excessive logistical burden.

the challenge:

the solution

Wing Wall Retrofit: Lightweight aluminum mono-panel flooring with integrated jacks, water drainage, and non-slip surface—eliminating plywood degradation and improving safety.

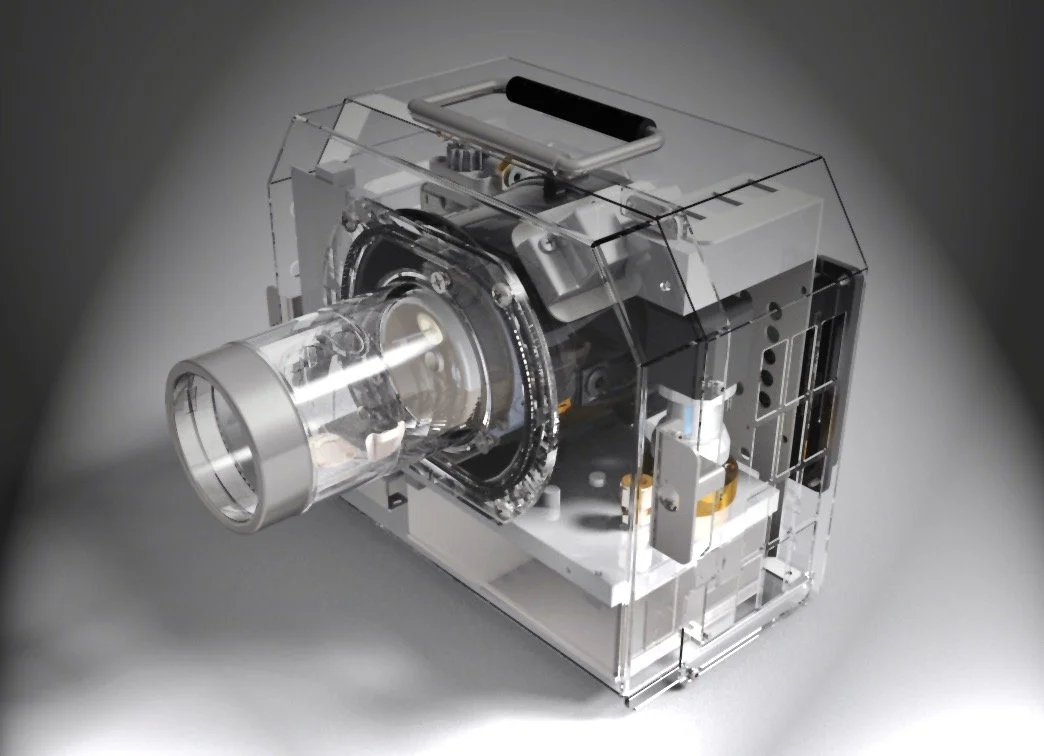

Closed-Flame Appliance Integration: Replaced legacy open-flame MBUs with JP-8 fired closed-combustion Airtronic Burner appliances, reducing heat, noise, and CO risks.

Integrated and Insulated Support Structure: Permanent mounted and collapsible support frame with insulated ceiling, enabling fast, safe setup with fewer personnel.

Generator Slide-Out Assembly: Enabled safe fueling, improved airflow, and easier maintenance by relocating the 10kW AMMPS generator on a sliding mount.

Integrated Thermal Modeling: Babington conducted CFD modeling and thermal analysis to evaluate interior heat loads and guide ECU selection.

LED Lighting Upgrade: Replaced legacy fluorescent fixtures with energy-efficient LED systems, maintaining normal, blackout, and emergency lighting functionality.

key innovations:

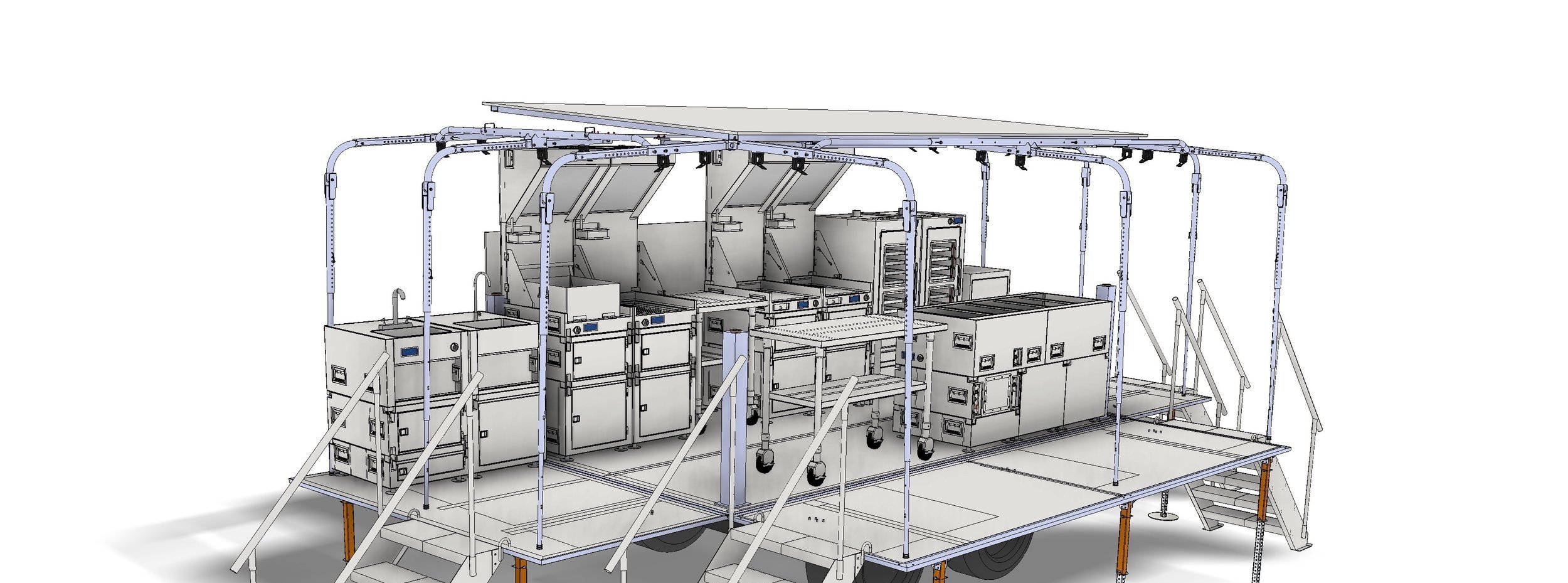

CK-E Deployment: From Transport Mode to Operational Mode

The outcome

The Enhanced Containerized Kitchen (CK-E)

BEFORE: Legacy CK System

-

Interior of Legacy CK Kitchen

Inside the legacy CK, showing the central cook station beneath the overhead exhaust hood and ventilation system, with the food preparation area behind it.

-

Operator Exposure to Heat and Emissions

A food service specialist prepares meals over an open-flame MBU burner, working in extreme heat and directly exposed to carbon monoxide (CO) and combustion byproducts.

-

Open-FLame Combustion

A close-up of the MBU’s open flame, highlighting the intense radiant heat and direct release of combustion byproducts into the kitchen environment.

-

Degraded Wing Wall

The CK’s expandable wing wall showing signs of structural fatigue, water damage, and corrosion after years of field use, environmental exposure, and failing winch and cable systems.

-

Damaged Flooring

The CK’s original plywood floor, degraded by trapped moisture, corrosion, and heavy foot traffic in high-use zones.

-

Deteriorating Canvas

The insulated fabric cover exhibits tearing, UV wear, and water intrusion—contributing to poor insulation, difficult setup, and costly replacement.

AFTER: Upgraded CK-E System

-

Modernized Kitchen Layout

The interior of the CK-E shows closed combustion appliances and an open floor plan that improves workflow, thermal comfort, and operational flexibility.

-

Flexible Serving Line

Foodservice personnel operate efficiently moving through the serving line. The new kitchen layout supports both internal and external serving line configurations, allowing units to adapt based on mission needs and customer preference.

-

Closed Combustion Eliminates Open-Flame Hazards

Airtronic closed-combustion burners are integrated into all CK-E cooking appliances—eliminating open-flame hazards and dramatically reducing internal heat, noise, and CO exposure.

-

Lightweight Wing Walls with Electric Winch

Lightweight, drainable wing walls feature corrosion-resistant materials . An electric winch system replaces the legacy manual cable setup—improving safety, reliability, and ease of deployment.

-

Insulated Fabric Support Structure and Durable Flooring

An integrated fabric support structure also serves as an insulated ceiling—improving thermal comfort, setup time, and overall safety. The upgraded, water-resistant flooring withstands moisture and heavy use, eliminating the degradation issues of the original plywood design.

-

New Mechanical Room with Slide-Out Gnerator

The mechanical room has been reconfigured to include a slide-out generator mount assembly, allowing safe and easy access for fueling, maintenance, and operation. This design improves airflow and reduces noise inside the kitchen during use.