case study

Developing a Mobile Mass Feeding Capability for Domestic Response

Disaster relief mobile kitchen trailer (DRMKT)

the Customer:

U.S. Air National Guard

background:

In the wake of Hurricane Katrina in 2005, the U.S. Air National Guard (ANG) recognized a critical gap in its ability to provide large-scale feeding during domestic emergencies. To enhance readiness and response under the U.S. National Response Framework (NRF), the ANG established the requirement for a rapidly deployable, self-sustaining mobile kitchen solution capable of supporting mass care and feeding operations anywhere in the continental United States.

Design and deliver a highly mobile, diesel-fired Disaster Relief Mobile Kitchen Trailer (DRMKT) that provides immediate, reliable food service for up to 800 personnel per meal cycle in response to natural disasters and domestic emergencies. The system was designed to be towable by a heavy-duty pickup truck, optimized for safety, serviceability, and ease of deployment. It was also to feature improved accessibility and maintainability, be certified for C-130 air transport under ATTLA standards.

the objective:

Prior to the development of the DRMKT, the ANG relied on static, tent-based systems like the Single Pallet Expeditionary Kitchen (SPEK) for disaster response. While effective in certain scenarios, these stand-alone kitchens required significant setup time, infrastructure, and the ability to bring people to the food—a limitation during widespread emergencies when mobility, access, and speed are critical. The ANG needed a more agile solution: a fully mobile, self-contained kitchen capable of reaching affected populations when they couldn't reach centralized feeding sites. The challenge was to create a rugged, diesel-fired kitchen trailer that could be rapidly deployed, safely operated in austere conditions, and towed by a standard heavy-duty pickup—all while serving hundreds of people per meal cycle.

the challenge:

the Babington solution

High-Capacity Feeding: Supports feeding operations for up to 800 personnel per meal cycle, with a full suite of commercial-grade cooking and sanitation appliances, including griddle, ovens, skillet, field sanitation unit, refrigerator, and heated serving lines.

Airtronic Multi-Fuel Combustion System: Integrated Babington’s closed-combustion burner technology, optimized for diesel and all military distillate fuels (JP-8, F-24, Jet A, etc.). Thermostatically controlled appliances reduce fuel consumption by 40–60% compared to legacy systems.

Onboard Power & Shore Power Integration: Equipped with an 8kW onboard diesel generator and full shore power connectivity, allowing operation in austere environments or supported installations without sacrificing performance.

C-130 Air Transport Certification (ATTLA): Engineered to meet rigorous ATTLA certification standards for airlift by C-130, C-17, and C-5 aircraft—ensuring global rapid-response capability.

Self-Leveling and Expandable Features: Includes self-leveling jacks and a rear slide-out platform with serving window to increase operational space, improve ergonomics, and streamline service in uneven or constrained environments.

key innovations:

DRMKT Deployment During Presidential Inauguration Events

The outcome

Disaster Relief Mobile Kitchen Trailer (DRMKT)

DRMKT in Action

-

Road Transport

The DRMKT is fully integrated into a commercial-grade trailer platform designed for rapid over-the-road deployment. Its three-axle bumper-pull design allows for safe, stable towing by standard heavy-duty pickup trucks without the need for special equipment or permits.

-

Site Arrival and Setup

Upon arrival, the DRMKT deploys quickly with self-leveling jacks that stabilize the trailer on uneven terrain. The system requires no external setup crew and is mission-ready within minutes. A rear platform provides additional working space for cooking and serving operations, and an optional rear tent can be erected to cover the platform—offering protection from the elements and expanding the operational footprint for all-weather use.

-

Expandable Kitchen Layout

The DRMKT features a flexible kitchen layout with an integrated slide-out expansion that increases interior workspace by one-third when deployed. This added space enhances mobility, reduces operator fatigue, and improves workflow during high-volume meal prep.

-

Full Appliance Suite

The DRMKT features energy-efficient appliances that handle diverse menus and high-volume output. The kitchen includes a 30-gallon skillet, flat-top griddle, dual convection ovens, a tray ration heater, a tilting field sanitation unit (T-FSU), and a tilting heated serving line (T-HSL).

-

High-Capacity Meal Service

This commercial-grade configuration enables safe, flexible, and efficient food service—from bulk meal prep to UGR-H&S and UGR-A support, with full sanitation capabilities—all within a single, self-contained mobile platform.

-

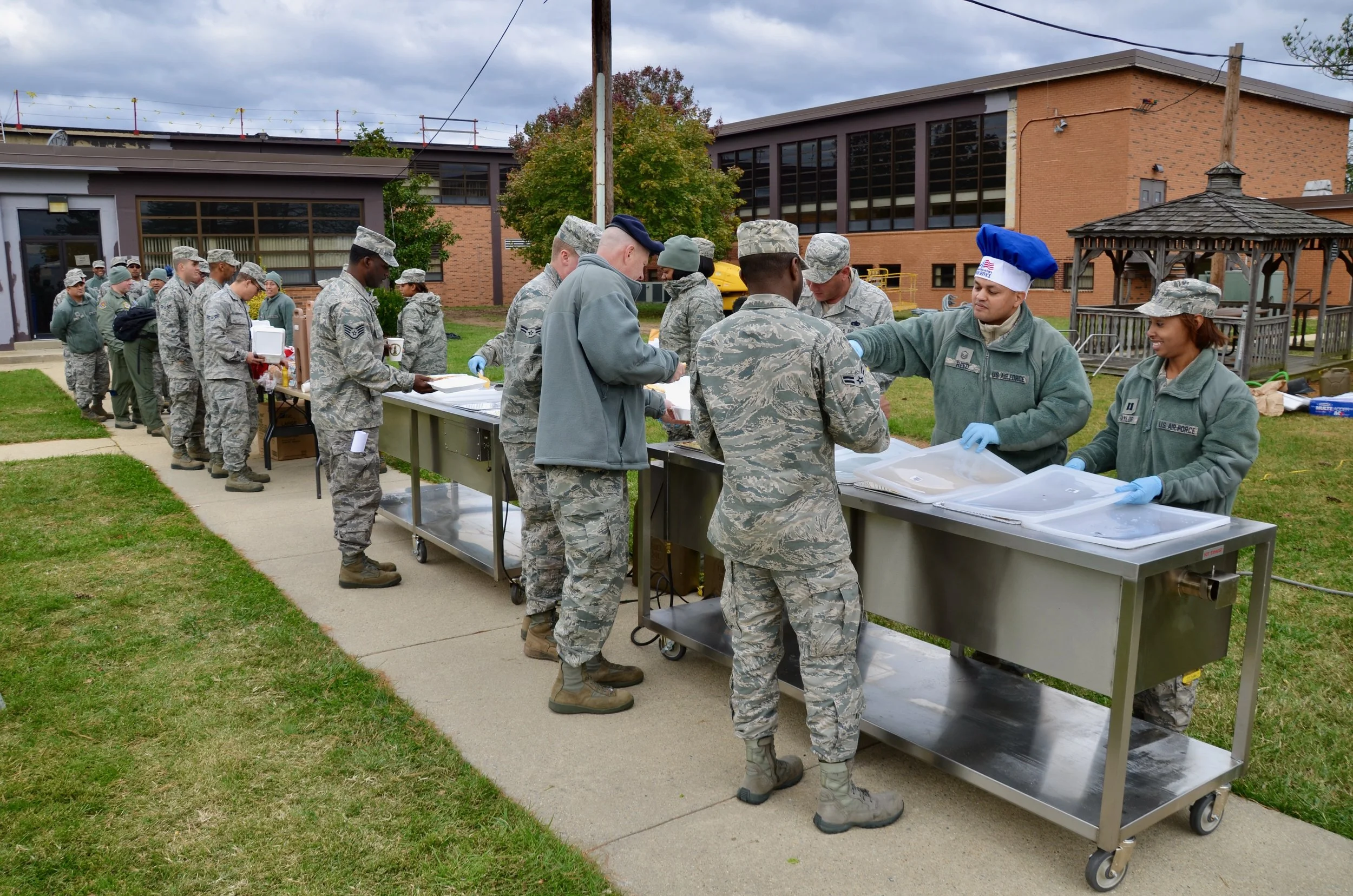

Flexible serving line at the point of need

The DRMKT features a heated serving line that can be deployed outside the trailer, enabling flexible meal distribution based on mission needs and site conditions. Whether serving first responders or disaster survivors, this configuration ensures hot meals are delivered quickly, safely, and with maximum reach in any environment.

Learn More About Off-Grid Sustainment